About

NETL’s Computational Science & Engineering (CSE) Directorate develops science-based simulation models, mathematical methods and algorithms, and software tools required to address the technical barriers to the development of next-generation technologies.

CSE works together with other directorates at NETL to generate information and understanding beyond the reach of experiments alone. Through the integration of experimental information and computational sciences, scientists and engineers can simulate variations more efficiently while saving time, money, and materials.

Thee CSE Directorate is organized into three research teams that collectively maintain NETL’s Computational Science and Engineering competency:

Computational Materials Team

The Computational Materials Team models materials at the atomic, molecular and microstructural scales, which enables a fundamental understanding of materials behavior and provides insight into subsequent materials development opportunities and optimization strategies.

Computational Device Engineering

The Computational Device Engineering Team develops multiphase computational fluid dynamics models required for predicting the performance of fossil energy devices, such as advanced combustion reactors, gasifiers, emissions capture, and carbon dioxide (CO2) capture units. The team has robust capabilities for linking models at multiple scales to increase simulation fidelity.

Data Analytics Team

The Data Analytics Team is developing and using data science methods to gain scientific insight from complex, high-dimensional, high-volume data sets from experiments and simulations conducted in support of energy technology development and is beginning to use machine learning to advance energy technology development.

Together, the CSE Directorate teams leverage world-class expertise and facilities to enable NETL’s simulation-based engineering approach for accelerating the development and deployment of novel fossil energy materials, processes and device designs.

Core Competencies & Capabilities

High-throughput computational modeling of multiphase flows

NETL is a leader in applying high-performance computing to computationally demanding multiphase flow problems, and in tackling challenging industrial-scale unit flow characterization and troubleshooting.

Development, validation, and application of multiphase flow tools

A part of the Computational Device Engineering Team, the Multiphase Flow Science group has produced a software portfolio of physics-based modeling codes to guide the design, operation and troubleshooting of multiphase flow devices, with an emphasis on fossil fuel technologies (e.g., coal gasifiers, CO2 capture devices and chemical looping).

NETL, Lawrence Berkley National Laboratory and the University of Colorado Boulder are conducting a multi-year effort to enable NETL’s open-source code MFiX to run on exascale computers. The project is supported by the Exascale Computing Project, a collaborative effort of DOE’s Office of Science and National Nuclear Security Administration. This effort will increase the scale and speed capabilities of MFiX, enabling it to simulate with higher fidelity reactors used in fossil energy technologies. The simulations will help reduce the risks, costs and time required for scaling up laboratory designs to industrial sizes, maximizing the benefits of high-performance computing for U.S. economic competitiveness.

Experimental activities

Experimental investigation of fluidization behavior and technology applied to coal combustion, gasification, and emissions clean-up. The MFS Group’s Multiphase Flow Analysis Laboratory includes reacting experimental units, enabling generation of well-characterized multiphase flow data at different length and time scales to aid in understanding complex fluidization behavior in reactors, thereby underpinning the development of mathematical models and validating software code. Experiments result in comprehensive data sets for validation, and the experimental units provide platforms for development and validation of novel measurement techniques.

Computational modeling of materials

First principles quantum mechanics calculations, classical and quantum molecular dynamics, Monte Carlo simulations, microkinetic modeling, and mesoscale modeling are used by the Computational Materials Team to characterize materials properties involved in diverse applications of interest such as catalysts and electrocatalysts, solid and liquid membranes for gas capture and separation, oxygen carrier materials, materials for solid-oxide fuel cell applications, and novel nanostructured materials for energy conversion and the development of gas sensors.

High-throughput computational screening

Designing materials or novel alloy compositions with controlled properties, assessing the materials’ thermomechanical and microstructure evolution under heat or electromagnetic treatments, optimization of their performances under diverse process conditions, and assessment of their performance-to-cost ratio.

Key Facilities

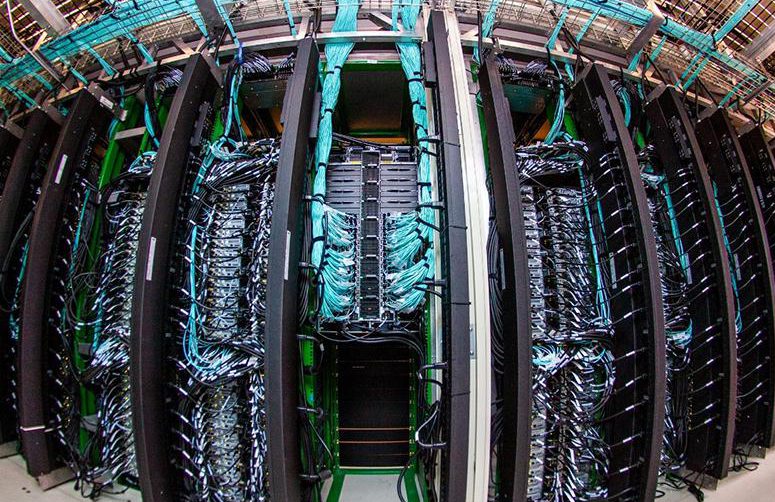

JOULE 2.0

Joule 2.0 is being installed and is designed to be a 5.62 PFLOP (one quadrillion floating-point operations per second) supercomputer that enables the numerical simulation of complex physical phenomena. Joule 2.0 provides computational throughput to run high-fidelity modeling tools at various scales ranging from molecules to devices to entire power plants and natural fuel reservoirs. Facilities associated with Joule allow for enhanced visualization and data analysis, as well as data storage capabilities that enable researchers to discover new materials, optimize designs, and predict operational characteristics

Data Analytics Center of Excellence

The Data Analytics Center of Excellence allows NETL to explore problems in machine learning, artificial intelligence, data mining, and data analytics and is specifically designed to house, move, and process multiple petabytes of data using a variety of cutting-edge algorithms developed inhouse and with our corporate and university research partners.

Visualization Centers

Visualization Centers allow NETL researchers to visualize massive amounts of data in Pittsburgh, Pennsylvania; Morgantown, West Virginia; and Albany, Oregon.

Notable Achievements

- Predictions of separations performance of materials for lower-cost carbon capture—CSE demonstrated ahigh-throughput computational methodology to identify promising mixed-matrix membranes for gas separations applications, such as for post-combustion carbon capture.

- Gasifier commercialization—MFiX modeling of KBR and Southern Company’s TRIG™ gasifier underpinned the scale-up of transport gasification technology to commercialization.

- Radioactive waste treatment characterization—The MFS group modeled fluidized bed reformers in the Integrated Waste Treatment Unit (IWTU) at the Idaho Cleanup Project for treatment and disposal of radioactive sodium-bearing liquid waste. Simulations helped to understand the chemical and hydrodynamic behavior inside the vessels and provide data to assist the IWTU project and help to expedite the start of operation of this facility.

- Development of extreme environment materials—CSE used computational modeling tools to gain a fundamental understanding of high-entropy alloys (HEAs) formation and their properties and developing high-performance HEAs for high-temperature fossil energy applications.

- Development of gold nanoclusters as catalysts for CO2 to CO conversion—Computational visualization of Au-Cu nanocluster structures, computational generation of structural, electronic and vibrational information, computational electrochemistry-based simulation of catalytic reactions, and density functional theory calculations performed on NETL’s Joule supercomputer, underpinned development of improved catalyst structures using less precious metal content. This development paves the way for less expensive CO2 utilization catalysts that can convert CO2 and water into synthesis gas (CO + H2).